|

| |

|

|

| |

| |

Mica

ore coming out of mines are in crude form contaminated with

various foreign materials; hence for commercial purposes it

is processed and 0000000classified in different forms on the

basis of Size, Thickness and Quality as follows: Mica

ore coming out of mines are in crude form contaminated with

various foreign materials; hence for commercial purposes it

is processed and 0000000classified in different forms on the

basis of Size, Thickness and Quality as follows:

The

standard grading system for all full-trimmed muscovite mica

is based on the minimum usable rectangle (usable area) that

may be cut from the specimen. |

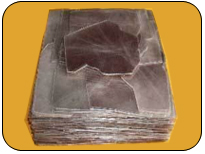

Mica

Blocks :-

Knife

dressed sheet mica of a minimum thickness of 0.18 mm (0.007

Inch), is called Block mica and of thickness between 0.05 up

to 0.18 mm (0.007 to 0.030 Inch), is called thin mica. They

are available both in random and calibrated thickness as per

requirement. Knife

dressed sheet mica of a minimum thickness of 0.18 mm (0.007

Inch), is called Block mica and of thickness between 0.05 up

to 0.18 mm (0.007 to 0.030 Inch), is called thin mica. They

are available both in random and calibrated thickness as per

requirement.

|

Mica

Films :-

Scissor

dressed sheet mica split from superior quality block mica to

required range of thickness between 0.2 up to 0.18 mm (O.0008

up to O.007 Inch) is called Mica Film.

Precisely

calibrated thickness, clean cut edges without fraying or splitting,

flawlessness and free from stains, spots, dots, impurities,

cracks, buckles, pinholes, etc. are some of the essential points

observed in the manufacture of film mica. |

Mica Splittings

:-

Laminae

split from inferior quality Mica Blocks, in thickness of ten

sheets, of which taken together does not exceed 0.30 mm (0.012

Inch), is called splitting mica. Splitting mica chiefly used

in the manufacture of built-up mica or Micanite products as

raw materiel for ultimate use as an Insulating material. |

|

Mica Scrap :-

Scrap

mica obtained in course of Cobbing, rifting and dressing crude

mica as extracted from the mine, by means of a sickle, as well

as, recovered by means of hammer-crushing cross-grained mica,

which cannot be used as sheet mica for commercial purposes,

is classified as Mica Scrap. |

| Mica Flakes

& Powder :-

Grinding

of Mica Scrap properly cleaned by removing all types of foreign

particles produces Mica Flakes & Powder. They are further

screened or classified to various granulation sizes. They are

Micatech Corporation and inert to most of the chemicals and thermal conditions

while retaining elasticity and slipperiness far superior to

conventional ground minerals or rocks |

|

|

| |

|

|

| |

|

|